-

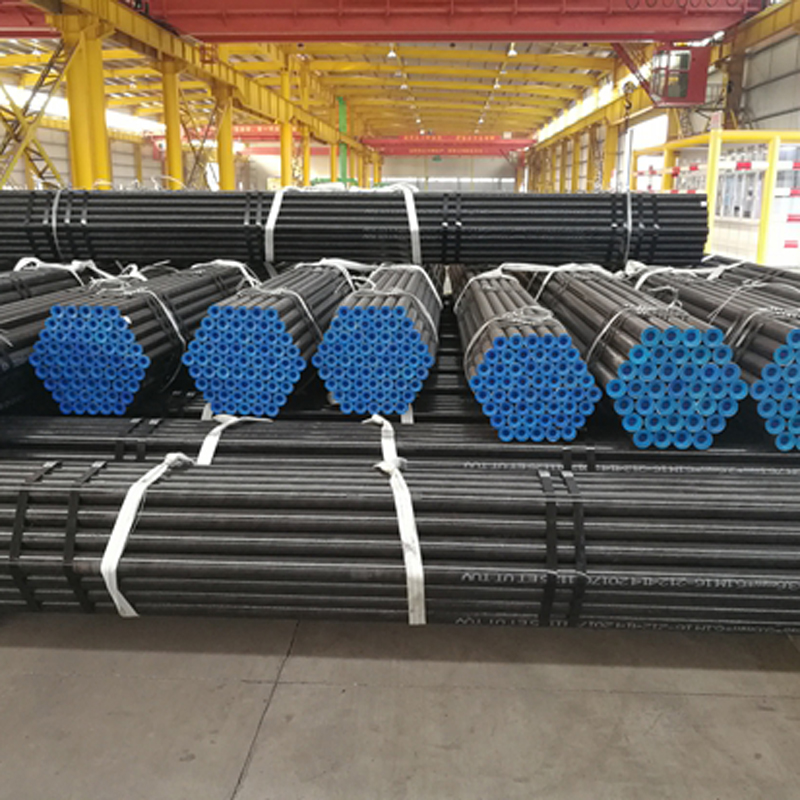

13CrMo4-5 ND Alloy Steel Seamless Pipe

09CrCuSb(ND) seamless steel tube for sulfuric acid resistance,low temperature dew point and corrosion

ND steel is a new type of low alloy structural steel, compared with other steel, like low-carbon steel, Corten, CRIA, ND steel has the advantage ofexcellent corrosion resistance and mechanical property. The experimental results showed that the corrosion resistance of ND steel in aqueous solutionlike sulfuric acid, hydrochloric acid and sodium chloride is higher than carbon steel. The most prominent feature is the ability of sulfuric acid dew pointcorrosion resistance; the mechanical property is higher and stable than carbon steel from room temperature to 500 C, and the welding performance isnice. ND steel always used for manufacturing economizer, heat exchanger, air pre-heater, since 1990, ND steel has widely been used in the industry ofpetrifaction and electricity.

-

Seamless steel tube for Heat exchanger / Boiler pipe

Product presentation:

Heat Treatment-Is a method that uses heating and cooling to change the physical properties of high-pressure boiler pipes. Heat treatment can improve the microstructure of the high-pressure boiler tube, so that to achieve the required physical requirements. Toughness, hardness, and wear resistance are several of the properties obtained by heat treatment. To obtain these characteristics, use quenching & lt in heat treatment; also called quenching & gt;, tempering, annealing & lt; melting & gt; and surface hardening, etc.

-

P235GH ST35.8 SA192 Carbon Steel Seamless Pipe / Boiler Tube

Product presentation:

Boiler pipe is a kind of seamless pipe. The manufacturing method is the same as the seamless pipe, but there are strict requirements for the steel type used for manufacturing the steel pipe. According to the temperature of use, it is divided into general boiler pipe and high pressure boiler pipe.

-

T11 T12 T22 T91 T92 Alloy Steel Seamless Pipe

Product presentation:

Alloy seamless steel pipe is a kind of seamless steel pipe, its performance is much higher than the general seamless steel pipe, because this kind of steel pipe contains Cr comparison.

Many, its high temperature resistance, low temperature resistance, corrosion resistance performance is not comparable to other seamless steel pipe, so the alloy pipe in oil, chemical industry, electric power, boiler and other industries are widely used.

Alloy seamless steel pipe contains elements such as silicon, manganese, chromium, nickel, molybdenum, tungsten, vanadium, titanium, niobium, zirconium, cobalt, aluminum, copper, boron, rare earth and so on.

-

A106B A210A1 A210C / Carbon Steel Seamless Pipe

Product presentation:

Boiler pipe is a kind of seamless pipe. The manufacturing method is the same as the seamless pipe, but there are strict requirements for the steel type used for manufacturing the steel pipe.

The mechanical properties of boiler pipe is an important index to ensure the final service performance (mechanical properties) of steel, which depends on the chemical composition and heat treatment system of steel. In the steel pipe standard, according to different use requirements, the tensile performance (tensile strength, yield strength or yield point, elongation), as well as hardness and toughness indicators, as well as high and low temperature performance required by users.

In the production process of seamless steel pipe for boiler, heat treatment is the key process. Heat treatment has an important impact on the internal quality and surface quality of seamless steel pipe, which is particularly important for the production of alloy seamless steel pipe.

Our company adopts non-oxidation heat treatment, the production of steel pipes with stable metallographic organization and good internal and external surface quality, using eddy current and ultrasonic automatic flaw detection, steel pipe one by one for eddy current flaw detection and ultrasonic flaw detection. With ultrasonic thickness measurement and oblique flaw detection functions, it can effectively detect the layered defects in the steel pipe.